Warm-Aging 3-Stage-Processing VS Warm-Aging 2-Stage-Processing

I've been writing about and experimenting with Low Temp Aging (Warm-Aging), for a few years. However, years before writing about this method, I used Low-Temp-Aging after reading about it in Modernist Cuisine. In the MC books, which were written in 2011, the Warm-Aging process is not directly addressed but is kind of spread out over the books. In this post, I will not give you all the background on this method, but if you want to, you can read about it HERE and HERE. In addition to those links, here's one more in which I contrast 104℉ to 113℉. In these links, I provide some science and some insight from many sources.

I've been writing about and experimenting with Low Temp Aging (Warm-Aging), for a few years. However, years before writing about this method, I used Low-Temp-Aging after reading about it in Modernist Cuisine. In the MC books, which were written in 2011, the Warm-Aging process is not directly addressed but is kind of spread out over the books. In this post, I will not give you all the background on this method, but if you want to, you can read about it HERE and HERE. In addition to those links, here's one more in which I contrast 104℉ to 113℉. In these links, I provide some science and some insight from many sources.

I first read about the terminology "Warm-Aging" (Somes times referred to LTLT Low-Temp-Long-Cook) in 2008 over at EGullet-Forums but did not start playing around with this method until about 2010. Although, in 2010, I was still learning about the method of Sous-Vide cooking, so I use the word "Playing around very "loosely." My knowledge base was in its infancy stage at that juncture, and after some years, I know just a little bit more.

Egullet Forums is a Society for Culinary Arts Letters. It's dedicated to the advancement of culinary Arts. There's a list of names that post in the forums you will surely recognize, but the two that stand out were Douglas Baldwin and Nathan Myhrvold. These two giants have contributed more to Sous-Vide-Cooking than everyone combined. I remember reading about the MC-Books way before they were published in 2011 over at Egullet. Baldwin and his free online source "Practical Guide to Sous Vide Cooking" blazed the path for everyone. In my opinion, Baldwin single handily unraveled the mysterious cooking method know as Sous-Vide for the masses.

Recall that enzymes make up a significant portion of the sarcoplasmic proteins. The sarcoplasmic calpains and lysosomal cathepsins are especially important in aging or conditioning. These enzymes catalyze the hydrolysis of one or more of the proteins — calpains the Z line proteins and cathepsin the myosin, actin, troponin, and collagen proteins. Dry aging is usually done at 1–3.3◦C/34–38◦F with about 70% humidity for 14 to 45 days. Higher temperature aging is also possible, see (Lawrie, 1998, pp 239– 40); Myhrvold et al. (2011) found that even 4 hours at 45◦C/113◦F can significantly improve tenderness. (Lawrie (1998) notes that at 49◦C/120◦F, that tenderness is particularly increased but that it has a somewhat undesirable flavor.)

|

| Modernist Cuisine 2011, many more through books. |

So what prompted me to contrast these two sets of standards? About 6-Months ago, I started using Sous-Vide Probes using Foam-Tape. The Foam-Tape allows you to pierce the bag with a small diameter SV-Needle without risking water infiltrating the vac bag. This allowed me to monitor Temps and collect data for future posts, which has been indispensable on many levels.

So what prompted me to contrast these two sets of standards? About 6-Months ago, I started using Sous-Vide Probes using Foam-Tape. The Foam-Tape allows you to pierce the bag with a small diameter SV-Needle without risking water infiltrating the vac bag. This allowed me to monitor Temps and collect data for future posts, which has been indispensable on many levels. One of the first things I noticed is how Heat-Transfer works and the symbiotic relationships between Food and Bath. After processing several proteins and looking at the data, I was intrigued by the proportionate relationship to protein thickness and ascending temperatures. I've collected data from over 30-Proteins, and results have been fascinating.

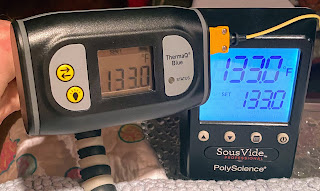

Before I give you my opinions, I wanted to highlight one essential component of this post. I have 5-Immersion-Circulators, but the PolyScience is the only one that can be calibrated. I used a couple of Themoworks devices to calibrate the I.C.

I used Tri-Tips as my muse because they are one of my favorite cuts, and I have processed over 200 of them using Sous-Vide. I attempted to use 2-Similar Tri-Tips in both weight and thickness. I bought a cryovac bag from Costco that had 7 of them, which gave plenty to choose from. At their thickest part, they measured 54mm (2.13") and 56mm(2.20").

Parameters- Most people choose proteins that measure from 1.25-2-Inches. Additionally, most people do not Warm-Age beyond a total of 2-Hours, but using probes, I knew those temps were not adequate. Don't misunderstand what I am saying, although some will. I am not saying your proteins processed at 2-Hours didn't taste good, but I will say those time parameters didn't take advantage of the LTLT- Low-Temp-Long-time cooking method (Warm-Aging).

⤋🔴⤋🔴⤋🔴⤋🔴⤋🔴⤋🔴⤋🔴⤋🔴⤋🔴⤋🔴⤋🔴⤋🔴⤋🔴⤋🔴⤋🔴⤋🔴⤋🔴⤋🔴⤋🔴⤋🔴⤋🔴⤋🔴

3-Stage- At the 90-Minute Mark, the internal temp only reached 98.4f, no near where the 104f needed to put enzymes into hyperdrive. That being said, the outside of the protein was at 104f, and a percentage of the gradient layers were too. But no significant time was ever spent at 104f before the temp was increased to 120f. Somewhere below the two-hour mark, the temp hit 104f, but that's only because of the temp increase to 120f. For those that would choose a 1-Hour processing time, the internal temp was 88.2f.

After increasing temp to 120f and waiting out the additional 90-Minutes, the internal temp rose from 98.4f to 118.3f. Hypothetically, if we would have used 1-hour for 104f and 120f, we wouldn't have gotten very far. I am guestimating after increasing temp to 120f at the 1-Hour mark we would have gotten maybe to 101f. I will offer this one concession and caveat that the outcomes will be different based on different thicknesses. NOTE: (Lawrie (1998) notes that at 49◦C/120◦F, that tenderness is particularly increased but that it has a somewhat undesirable flavor.)

I'll bring this up but take it with a grain of salt. I did not perceive any "Undesirable Flavors." I was hesitant to include this because the protein never reached 120f. Contrasting both Tri-Tips, I will say the tastes were slightly different, and I preferred the 113f one over the 120f. Again the internal temps never got there. No Tri-Tips were ever sacrificed, and every morsel was eaten.

⤋🔴⤋🔴⤋🔴⤋🔴⤋🔴⤋🔴⤋🔴⤋🔴⤋🔴⤋🔴⤋🔴⤋🔴⤋🔴⤋🔴⤋🔴⤋🔴⤋🔴⤋🔴⤋🔴⤋🔴⤋🔴⤋🔴

2-Stage Although this is my go-to Warm-Aging temp, the 3-Hour Processing Time did not reach the desired temp of 113f. At the 3-Hour Mark, it never exceeded 112.8f. That being said, this is still my go-to temp for Warm-Aging. It did spend some time below 105f, which put the enzymes into overdrive. How much? I have no clue. As noted above, the outside layer and inner gradient layers were at 113f. Maybe this is why I preferred this temp?

⤋🔴⤋🔴⤋🔴⤋🔴⤋🔴⤋🔴⤋🔴⤋🔴⤋🔴⤋🔴⤋🔴⤋🔴⤋🔴⤋🔴⤋🔴⤋🔴⤋🔴⤋🔴⤋🔴⤋🔴⤋🔴⤋🔴

Below the Chart, I will offer some opinions with caveats. Take what I am saying as face-value and nothing more.

For the most part and generally speaking, society as a whole considers animal proteins to be a cesspool of pathogens. More people get sick from cross-contamination than they do from meat. If we really wanted to be consistent, we would treat fish like we do poultry. The chances of you getting sick from produce are higher than eating protein that has not been prepared by the standards laid out by the FDA/USDA. If Gov. was serious about protecting everyone, they would tell you to pasteurize produce and fruit before consuming. Modern Cuisine Books have dedicated whole chapters to Food Safety rules and History, Food & Health, Microbiology for Cooks, Understanding the FDA Rule book, and Hygiene, etc. I would suggest everyone read them, including their footnotes too. In fact, let me add you need to read Baldwin's references also. The references/footnotes/bibliography is where you truly can decipher fact from fiction.

For the most part and generally speaking, society as a whole considers animal proteins to be a cesspool of pathogens. More people get sick from cross-contamination than they do from meat. If we really wanted to be consistent, we would treat fish like we do poultry. The chances of you getting sick from produce are higher than eating protein that has not been prepared by the standards laid out by the FDA/USDA. If Gov. was serious about protecting everyone, they would tell you to pasteurize produce and fruit before consuming. Modern Cuisine Books have dedicated whole chapters to Food Safety rules and History, Food & Health, Microbiology for Cooks, Understanding the FDA Rule book, and Hygiene, etc. I would suggest everyone read them, including their footnotes too. In fact, let me add you need to read Baldwin's references also. The references/footnotes/bibliography is where you truly can decipher fact from fiction. A Cautionary Tale- When you think of food safety, what are your first thoughts? I'm only guessing here, but I bet it's Poultry, Pork and Ground beef (Note: I do not eat pork). How about other proteins? Do you eat Oysters or Clams (Note: I don't eat Shellfish). How about Veggies and fruits? The very nature of eating poses a risk, so what to do? We certainly can't stop eating? With a commonsense approach to food preparation, cleanliness, cooking, we can mitigate most of these concerns. Let's not forget sourcing the protein and starting out with great ingredients. Sous-Vide-Processed food that uses appropriate Time & Temperatures can alleviate many Food Safety issues.

Beware of mechanically tenderized protein (Jaccarded). As of May 2016, the USDA now requires everyone to label packages appropriately with cooking instructions. In the labeling, the distributors use the tiniest of print, so make sure to look at the labeling and cooking instructions. It's all about covering the AZZ's. What's wrong with mechanically tenderized meat? Surface pathogens (if there are any) are forced into the protein. Generally speaking, the interior of the muscle is sterile, provided it has not punctured or pierced. Read Costco's label on their meat that sitting out in the food case. I believe it says to cook to 160f. And I am pretty sure the FDA says to cook and hold at 145f for 3-Minutes. Of course, with Sous-Vide cooking, the ability to pasteurize at low temps is possible. I wrote an article on Mechanically-Tenderized-Protein and Sous-Vide, and it can be found HERE.

The plethora of books, articles, papers, online-sources has helped me create what I will most likely adopt when I Warm-Age proteins. Let me give you a caveat for this next section. Read my disclaimer at the top. These are advanced techniques and should not be attempted unless you have a full grasp of food safety standards. Don't take any unnecessary risks. I have a thorough understanding of pathogen modeling and know the risks. And knowing how to mitigate those risks are essential before using this method. Let me add this one more thing again. Use high-quality ingredients.

The plethora of books, articles, papers, online-sources has helped me create what I will most likely adopt when I Warm-Age proteins. Let me give you a caveat for this next section. Read my disclaimer at the top. These are advanced techniques and should not be attempted unless you have a full grasp of food safety standards. Don't take any unnecessary risks. I have a thorough understanding of pathogen modeling and know the risks. And knowing how to mitigate those risks are essential before using this method. Let me add this one more thing again. Use high-quality ingredients.

In a perfect world, aka Utopia, there's no such thing as food pathogens or a need safety standards. There are no diseases, plagues, or autolysis. But sadly, we don't live in that world, so we have to use a common-sense approach to food safety. With that be forwarned, I am not going to be using any super conservative model for this method of cooking.

In a perfect world, aka Utopia, there's no such thing as food pathogens or a need safety standards. There are no diseases, plagues, or autolysis. But sadly, we don't live in that world, so we have to use a common-sense approach to food safety. With that be forwarned, I am not going to be using any super conservative model for this method of cooking.

Building on what I have read and ascertained, again living in a perfect world I reached a few unyielding conclusions. In order to achieve all the benefits of Low-Temp-Long-Time (Warm-Aging), one would have to do the following. Protein would need to reach equilibrium (bath and food are the same temps) then hold that temp for a while (For a while?). That can be difficult to do and stay within a reasonable food safety standard. Although this might work with some very-thin cuts of meat like .75".

I read some crazy stuff over at Egullet Forums in which Chefs played around with LT-LT (Low-Temp-Long-Time) and processed proteins over 15-plus hours at very very low temps. Is it safe? In most cases, the Chefs processed the protein to achieve a pasteurization way above a 7D Log Reduction. For some perspective, a 7D means that 99.99999% of pathogens have been killed. A 7d Log-Reduction is what the FDA/USDA requires for poultry. When you process meats longer to tenderize, you undoubtedly will achieve a very high Log-Reduction. It's important to note that Chefs, Authors, Scientists that publish their work will always err on the side of caution. What they do in private, write in forums, is entirely different in most cases from their published work.

Going forward, I will do some things differently. I will offer some of my thoughts and insights. I can't take credit for all of this because I am building on what has already been done by the Giants in this field. I am standing on their shoulders.

Just to give you some ideas about what they write over at EGullet forums...... click on pic to make bigger. These guys on Giants in the field. This is just a snippet.

The plethora of books, articles, papers, online-sources has helped me create what I will most likely adopt when I Warm-Age proteins. Let me give you a caveat for this next section. Read my disclaimer at the top. These are advanced techniques and should not be attempted unless you have a full grasp of food safety standards. Don't take any unnecessary risks. I have a thorough understanding of pathogen modeling and know the risks. And knowing how to mitigate those risks are essential before using this method. Let me add this one more thing again. Use high-quality ingredients.

The plethora of books, articles, papers, online-sources has helped me create what I will most likely adopt when I Warm-Age proteins. Let me give you a caveat for this next section. Read my disclaimer at the top. These are advanced techniques and should not be attempted unless you have a full grasp of food safety standards. Don't take any unnecessary risks. I have a thorough understanding of pathogen modeling and know the risks. And knowing how to mitigate those risks are essential before using this method. Let me add this one more thing again. Use high-quality ingredients.  In a perfect world, aka Utopia, there's no such thing as food pathogens or a need safety standards. There are no diseases, plagues, or autolysis. But sadly, we don't live in that world, so we have to use a common-sense approach to food safety. With that be forwarned, I am not going to be using any super conservative model for this method of cooking.

In a perfect world, aka Utopia, there's no such thing as food pathogens or a need safety standards. There are no diseases, plagues, or autolysis. But sadly, we don't live in that world, so we have to use a common-sense approach to food safety. With that be forwarned, I am not going to be using any super conservative model for this method of cooking. Building on what I have read and ascertained, again living in a perfect world I reached a few unyielding conclusions. In order to achieve all the benefits of Low-Temp-Long-Time (Warm-Aging), one would have to do the following. Protein would need to reach equilibrium (bath and food are the same temps) then hold that temp for a while (For a while?). That can be difficult to do and stay within a reasonable food safety standard. Although this might work with some very-thin cuts of meat like .75".

I read some crazy stuff over at Egullet Forums in which Chefs played around with LT-LT (Low-Temp-Long-Time) and processed proteins over 15-plus hours at very very low temps. Is it safe? In most cases, the Chefs processed the protein to achieve a pasteurization way above a 7D Log Reduction. For some perspective, a 7D means that 99.99999% of pathogens have been killed. A 7d Log-Reduction is what the FDA/USDA requires for poultry. When you process meats longer to tenderize, you undoubtedly will achieve a very high Log-Reduction. It's important to note that Chefs, Authors, Scientists that publish their work will always err on the side of caution. What they do in private, write in forums, is entirely different in most cases from their published work.

Going forward, I will do some things differently. I will offer some of my thoughts and insights. I can't take credit for all of this because I am building on what has already been done by the Giants in this field. I am standing on their shoulders.

1- I will Warm-Age meat that does not exceed 2.25".

2- As always, I will pasteurize.

3- I will Process at 113f for 4-Hours. (3A-After processing 4-Hours raise temp to desired final temp. I always add boiling water to the cooking vessel to hasten climb of final temp.)

4- In the Forums and in MC Books, they suggest pasteurizing the surface to kill surface pathogens. It's just one more way to mitigate and alleviate any potential issues. I wrote an article about pasteurizing the surface of protein HERE.

4- If I exceed 4-hours, I am not going to tell anyone, but I will definitely pasteurize the surface.

5- Starting the at temp 120f than lowering to 113f is my go-to now. It gives you a headstart and hastens the climb to 113f.

Reminder- I've written about this before, but it's essential to bring it up again. First, let say this- People get confused as to why we Warm-Age because we can achieve the same results by cooking longer, which is not entirely true under scrutiny. I.e., Tri-Tip Warm-Aged at 113f for 3, then finished at 133f for 8-Hours is likened to a Tri-Tip processed at 133f for 14-Hours. There are some differences, though. There's a noticeable variation in the fibrils and moisture. The Tri-Tip that was Warm-Aged held on to a larger percentage of moisture and had a much more pleasant mouthfeel.

Comments

Post a Comment