Neo & Morpheus explore Sous-Vide-Cooking & Food Safety

I began exploring the internet for information related to Sous-vide, and I think it was 2006 when I stumbled across Egullet Forums. If you have not checked out E-gullet Forums, it's a must. It's dedicated to the advancement of culinary arts. This is where the culinary giant's food scientists discuss food, theories, and just about everything under the sun. Before they publish their books or scientific papers, they go to the forums to discuss their ideas or views. It's worth mentioning that Nathan Myhrvold and Dr. Baldwin contributed to the forums before and after they published their work. You may recognize other famous names too.

A Shout out to three Giants that has forever changed the way I cook food!!!

Many people are credited for the advancement of Sous-Vide, but in my opinion, everyone is negligible compared to Dr. Baldwin's contribution. He singled-handily made Sous-Vide a household name. And you did not have to buy a book because his material is online. People talk about Thomas Keller, Nathan Myhrvold, and Dr. Bruno Goussault, and they have their place in the culinary world, but it's Dr. Baldwin who made Sous-Vide what it is today. What source does everyone consult when they want to process something Sous-Vide? You guess correctly; it's Dr. Baldwin's book "A Practical Guide to Sous-Vide Cooking." When I began what I call a journey into this cooking method, had it not been for Dr. Baldwn, I would not be where I am today, and I am sure many others feel the same.

Although not related to Sous-Vide, Harold McGee is an excellent resource. A must-read, as well as his other books on food. I think I bought my first copy maybe 25-plus years ago. Anyhow, over the years, this has been my go-to for everything food. I've grown to love this book because I began to appreciate and understand the previously unexplored subjects as my knowledge base expanded.

If you continue reading, I assume you have taken the Red Pill and are willing to embrace some truths, and if you have stopped reading, you have decided to take the Blue Pill and remain forever blissfully ignorant.

If you continue reading, I assume you have taken the Red Pill and are willing to embrace some truths, and if you have stopped reading, you have decided to take the Blue Pill and remain forever blissfully ignorant.

A Cautionary Tale- When you think of food safety, what are your first thoughts? I'm only guessing here, but I bet it's Poultry, Pork, and Ground Beef. How about other proteins? Do you eat Oysters or Clams? How about Veggies and fruits? The very nature of eating poses a risk, so what to do? We certainly can't stop eating? We can mitigate most of these concerns with a commonsense approach to food preparation, cleanliness, sourcing, and cooking. Sous-Vide-Processed food that uses appropriate Time & Temperatures can alleviate many Food Safety issues.

What if I told you?- Not all proteins are created equal, and the so-called experts in the field are driven by political pressure and have failed to keep up with advances in Science (or deny Science). My culinary prowess comes from reading, testing, and experimentation, and with that, I've learned a thing or two. IN THE SO-CALLED GUIDEBOOKS, what I have found is often misleading and overseen by ignorance. The other issue could be they are too afraid to rock the boat or go against the prevailing philosophy. In other words, you can't get a straight answer. They often explain food and safety guidelines insufficiently and fail to address the contradictions. Look at our own USDA/FSIS and FDA (I am sure there are more) and all the misinformation. Here's the one example that comes to mind. In guidebooks and regulations, we are often told that the Danger Zone is 40f/40.4c-140f/60c. As most of us know, The Danger Zone is way more complicated, but they chose these numbers for whatever reason. I can only surmise they wanted to keep things simple or assumed we were too dumb to understand simple words. How can we store Eggs at 45f and hold food at 130f? Hmmm, are these numbers not in the Danger Zone?

(See MC Volume 1 page 160) "Yet when several U.S. meat-packing companies began doing such tests, in part to become eligible to export beef to Japan, the U.S. Department of Agriculture (USDA) responded by outlawing them. The USDA argues that the testing is "unnecessary" because "no scientific proof" that it is required exists, but how can proof be obtained unless you look. We believe the real motive for preventing testing is likely to be political pressure from the beef industry."

How, What, and Why? - I started down this path just to understand and collate all the information. But, dang, this was not an easy thing to do. I have scoured the internet, read all the relevant USDA/FSIS regulations (and additional links and literature), read Baldwins stuff, Modern Cuisine (Footnotes), and I've come away not confused but thoroughly well-read. Notwithstanding most of what I have learned, my opinions can be summed up into two categories. First: Government overreach, and it's for our own good. What do they say about good intentions? I'll attempt to paraphrase what MC wrote in Vol-1, pages 168-169. These words describe what I believe is happening, not MCs. Second: the Government wants to protect us from ourselves? The USDA/FSIS and FDA motto, IMO could be interpreted as "If a little is great, and a lot is better, then way too much is just about right," Mae West.

These experts in the field (using this word loosely) "rely on guesswork to develop standards" (MC Vol 1, page 168). All of the so-called experts make uncompromising statements that "food cooked to a standard is safe, but food cooked less than the standard is unsafe. This can never be literally true." (see-MC Vol 1, page 168). So what do they do? The experts in the field use worse-case scenarios even though Science does not back up their claim. Setting very high "D" (Log-Reduction) Levels sets up a fence around us for the day of reckoning. It's their claim to fame that their goal is to protect us. Does this sound like a big government?

Times and Temperatures will set you free- In other words, using a combination of Time and Temperature will kill pathogens. But which ones should you choose?

Before I discuss what Log Reductions are in layman's terms, I want to address what's behind the curtain. Here is one of those moments where you say duh, but then again, maybe not. It's what we call inattentional blindness, meaning it was always there but hidden in plain sight. How do we become blind to what is obvious? Unintentional or not, we get accustomed to taking things at face value.

So with that, this begs the inevitable but provocative statement that if the food contains no pathogens, it was never necessary to kill pathogens to any D-Level (Log Reduction) because they were never there. My statement above is tongue-in-cheek to point out the excessive regulations. The overabundance of caution and smidgen of liability concerns that the Government has established assumes that the general public is simple-minded. Moreover, though justified in their text, the governments' sardonic exaggerated doctrine and dogma will insult anyone who can read. Don't take anything at face value... "Trust but verify."

Before I continue, I want you to reflect on the following. Most people conclude that something must be a fact because it's been told to them many times and then reconfirmed because of practice. I.e., Searing the outside of a protein will seal in the juices...MYTH. In general, it's because of something they've read or heard repeatedly. I.e., Pork and Chicken must be cooked until an internal temperature of 165f is reached to kill pathogens. This statement is false and inaccurate. Wrong because if there are no pathogens present, there is nothing to kill, and we know that a combination of Time and Temperature kills pathogens and not just Temperature alone.

Before I continue, I want you to reflect on the following. Most people conclude that something must be a fact because it's been told to them many times and then reconfirmed because of practice. I.e., Searing the outside of a protein will seal in the juices...MYTH. In general, it's because of something they've read or heard repeatedly. I.e., Pork and Chicken must be cooked until an internal temperature of 165f is reached to kill pathogens. This statement is false and inaccurate. Wrong because if there are no pathogens present, there is nothing to kill, and we know that a combination of Time and Temperature kills pathogens and not just Temperature alone. I can't tell you how often I've heard people say that it's unsafe if "MEAT" is not cooked to a specific standard. What? Remember what I said earlier? But which standard are they referring to?

For the most part, and generally speaking, society considers animal proteins a cesspool of pathogens. Zealots who love hearing themselves talk use scare tactics about food contamination. These Zealots are likened to Chicken Little and exaggerate danger because they see everything through one lens. More people get sick from cross-contamination than they do from meat. If these so-called Zealots were true to their cause and wanted to be consistent in their alarmist beliefs, they would have you cook all produce and fruit.

For the most part, and generally speaking, society considers animal proteins a cesspool of pathogens. Zealots who love hearing themselves talk use scare tactics about food contamination. These Zealots are likened to Chicken Little and exaggerate danger because they see everything through one lens. More people get sick from cross-contamination than they do from meat. If these so-called Zealots were true to their cause and wanted to be consistent in their alarmist beliefs, they would have you cook all produce and fruit.  The CDC regularly sends out recalls for Salmonella and E.Coli but are primarily associated with prepackaged food and produce. The chances of you getting sick from produce are greater than eating protein that has not been prepared by the standards laid out by the FDA/FSIS. If the Government were serious about protecting everyone, they would tell you to cook all the produce before eating. Unfortunately, the most substantial risk you take to your health happens at the salad bar and not in your kitchen.

The CDC regularly sends out recalls for Salmonella and E.Coli but are primarily associated with prepackaged food and produce. The chances of you getting sick from produce are greater than eating protein that has not been prepared by the standards laid out by the FDA/FSIS. If the Government were serious about protecting everyone, they would tell you to cook all the produce before eating. Unfortunately, the most substantial risk you take to your health happens at the salad bar and not in your kitchen.

Before I continue, I want to be clear on this one point. I am not against Pasteurization! On the contrary, my preferences for texture, taste, and the times I choose often coincide with the published pasteurization standards. And more often than not, exceed them too. But with that, I love knowing why I do something and not because of something or what someone else has suggested or demanded. I am sure you have asked the same question...WHY?

What comes to mind when you see 7D or 6.5D in a Reduction Table? How about when you see a Time and Temperature in those same charts? Have you ever seen a 10D Chart (me neither)? If you exceed the T&T in those tables, what does that mean? Can you over-pasteurize? No, You Can Not!!!

How does one know if the protein is pasteurized? Sous-Vide Needle Probes are used with High-Density Closed Cell Foam Tape to monitor the protein's internal Temp without water getting into the bag. The Foam tape seals around the needle as it pierces the bag. My go-to is always Dr. Baldwin's well-established pasteurization tables if you do not have a probe. What did I do before his tables were published? Let's just say what I produced was not the safest or the greatest. Do I use probes now? Yes, on most occasions, but purely out of curiosity and to document my cooks.

How about those Apps for Sous-Vide? I've tried them all, and it's my opinion they are unreliable. Nevertheless, it's worth noting I've contrasted the apps T & T to Dr. Baldwin's tables and my probe cooks and have found the apps unreliable. So, if you do not have access to SV-probes, stick with Dr. Baldwin's tables. His tables are accurate and trustworthy.

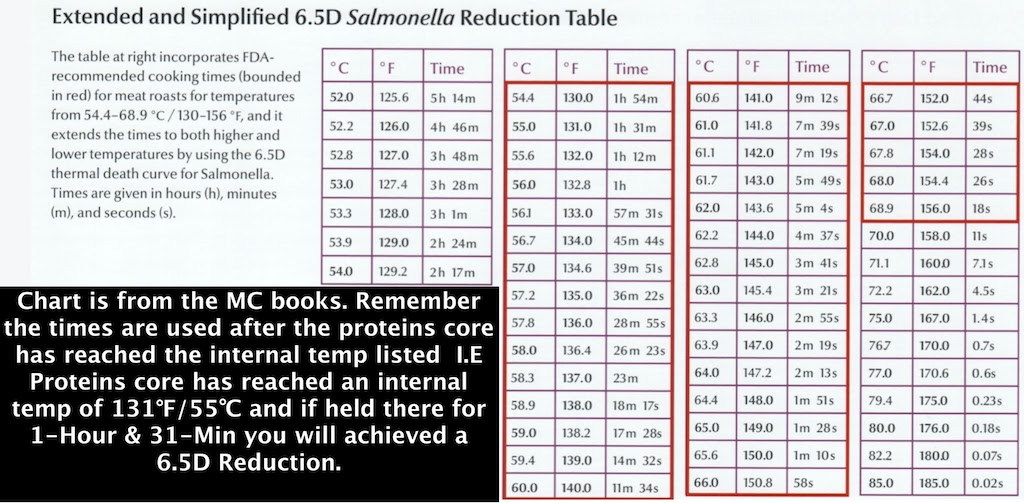

How do you use probes to pasteurize food? First, you need to find a Pasteruazaton table (I provided several below). Pasteurization is the combination of Time and Temperature. The higher the temperature, the faster the Pasteurization occurs. Pasteurization happens when the food is held at a precise temperature for a specific time. Once the protein reaches the target temperature, the clock begins; I.e., at a target temperature of 133℉, it would take 57m and 31 secs to achieve a 6.5d Log Reduction, and at 137℉, it would take 23-Min. But of course, you might want to go longer for proteins that need longer times to become tender, i.e., Flank steak, chuck, or Tri-tip.

Note: In my opinion, It is imperative to pasteurize food when serving immuno-compromised people, the elderly, pregnant or very young children, or those with compromised immune systems.

Other than a fillet or a fish, I can't think of another protein I've only cooked to an equilibrium state, which means I pasteurize 99.99% of the Time.

A 1-Log or 1D drop reduces a bacterial population by a factor of 10. Therefore, a 1D reduction means that 90% of the bacteria are killed, and 10% remain (A factor of 10 to 1). Remember what I said about the "D"? See "D" as a percentage and a decimal. The decimal form of 10% is written as .1.

If the Log Reduction is a whole integer (i.e., 2D), its value equals the number of nines in the percent. And guess what? That number also corresponds to the ZEROS. Stay with me... Remember the 1D? It has one Nine in the number 90% and one ZERO 10 (10 to 1). So a 2D is 99%, and 100 to 1 (the 100 has two Zeros). So 100 to 1 means that 1 out of 100 remained alive; hence, 99% were killed, and 1%=.01 are active.

3D is 99.9% 1000 to 1 (.1% =.001) , 4D is 99.99% 10,000 to 1 (.01% = .0001), 5D is 99.999% 100,000 to 1 (.001% = .00001), 6D is 99.9999% 1,000,000 to (.0001 = .000001) and 7D is 99.99999% 10,000,000 to 1 (.00001% = .0000001). The 6.5D math is harder to write out, but it equates to 99.99997% 3,170,000 to 1 ( 3.1545741E-5% = .00000031545741.)

Recap- If we have a 5D Log Reduction, that means we lowered the microorganisms by 100,000-fold, which means that 99.999% are dead and .001% or .00001 remain alive (100,000 to 1). There are five nines in 99.999% and five Zeros in 100,000.

|

| THERE ARE MANY CHARTS ONLINE AT THE FDA/FSIS WEBSITE |

There's a caveat when cooking at low temps like Sous-Vide, and assuming your I.C. has been calibrated, the Pasteurization can happen at a different time. Assuming, of course, you can achieve equilibrium (water & protein at the same Temp). Please read Modern Cuisine Vol 1 for more information. Pasteurization will occur if the food takes at least as much time to reach the core temperature. See the Chart below...

There's a caveat when cooking at low temps like Sous-Vide, and assuming your I.C. has been calibrated, the Pasteurization can happen at a different time. Assuming, of course, you can achieve equilibrium (water & protein at the same Temp). Please read Modern Cuisine Vol 1 for more information. Pasteurization will occur if the food takes at least as much time to reach the core temperature. See the Chart below...I asked this question earlier.... can you over-pasteurize? No, not really. Processing a protein beyond the Time listed in the charts increases the D-Level. This will happen with proteins that need extra Time for tenderization. I will show you how to compute the new D-Level for us' math geeks. Let's look at a chart.

Find a Time and Temperature in a Pasteurization Chart. Looking at a 6.5D chart, I know holding a protein at 131f for 1hr 31 minutes achieves a 6.5D. But, say you cooked it way beyond 91 minutes; would you know how to compute the new D-Level? If we know the Time for a 6.5D, calculating a 1D-Level is reasonably straightforward. Let's use a simple division.... 91-Minutes/6.5D = 14 minutes, which means it takes 14-Minutes to produce 1D-Level. So let's work backward..... I want to achieve a 6.5D, and we know that 1D takes 14-Minutes at 131f...14-Minutes X 6.5D = 91 minutes. How about a 7D? 7D X 14-Minutes = 98 minutes. Let's go extreme. Let's use Tri-Tip as an example. I like my Tri-Tip cooked at 133f, and looking at the chart, I see it needs 57 min and 31 Secs to pasteurize at a 6.5D. First, convert 31 secs to a decimal 31/60= .516667. The Total minutes are 57.516667/6.5D= 8.848718 Minutes per D-Level. Once the Tri-Tip reaches an internal temperature of 133f, we know that for every 8.848718 minutes that goes by, it achieves a 1D-Log Reduction. We know Tri-Tips can take a while, so let's say after the Tri-Tip reaches the target temperature, we cook it for 8 more hours. Convert 8 hours into minutes by multiplying 8-Hrs X 60-Minutes= 480 minutes. Take the total minutes and divide by the 1D- 8.848718... 480/8.848718 = 54.24D Log Reduction. See how easy that was.

Be honest when you think of the Danger Zone; what's the first thing that comes to mind? Could it be Kenny Loggins's famous song in Top Gun Danger Zone? Most likely not. Just for fun, go ahead and google Danger Zone and food. You will get hundreds of hits with pictures and temps. Most notable is the Temp 40℉-140℉/4.4℃-60℃, but as some know, this standard is misleading. The Danger Zone states that you can only have food at those temperatures for 4 hours before it becomes hazardous to your health. This disingenuous standard designed to keep us safe oversimplifies microbial growth patterns. Using the word disingenuous to describe the USDA/FDA/FSIS standards could be construed by many as very conservative, but they know the Science and advocate these ridiculous temps. It would be one thing to suggest these temps with caveats, but they don't. Not all temperatures within the danger zone are equally dangerous (See MC Vol 1 Chapter 1).

Let me assure the perception of the Danger Zone is ill-conceived and vastly overrated. The well-known numbers of 40f-140f simplify the microbial growth patterns (MC Vol 1 Chap 3 pg 175). Not all temperatures within the so-called danger zone are correspondingly dangerous.

Most food pathogens can be killed at temperatures above 120f, yet food safety rules tend to require temperatures much higher than that (MC VOL 1-PAGE 169).

Many sources say you need to process above 130f (one source I found suggested 129f)? And to be perfectly honest, I rarely ever go below 130f, but it would be nice to know why, don't you think. I've come across a couple of respected references that advocate 130f but fail to address the objective rationale behind this preference. Maybe it's because of the possibility that the Immersion Circulator could be off a few degrees? If you can, consider calibrating or, at a minimum, checking your temps with a quality probe like one from Thermoworks. If you cannot calibrate or want to err on the side of caution, process at higher temps.

No doubt, Safety is what we are concerned about, but to mitigate by having and having built-in safety margins that require you to increase the bath temp just in case is absurd.

Can you tell the difference between a few degrees based on color? I wrote an article that explores this very topic. It's titled Time to Temp? Can you tell which one is which?

Also, it's worth mentioning that a Pre-Sear will kill all surface pathogens, mitigating any concerns about pathogen proliferation as the interior of most unpunctured proteins is sterile. Of course, this applies to poultry as well. Note: Blanching in boiling water will work, too, but provides no benefit other than killing pathogens, whereas a Pre-Sear will begin a Maillard Reaction. Note 2: A Torch will work, too and has its place!!!

How Are Chickens Slaughtered and processed?

The Complex Origins of Food Safety Rules--Yes, You Are Overcooking Your Food.

U.S. agencies recommend temperatures and times far beyond those supported by science

By Nathan Myhrvold, Chris Young, Maxime Bilet on March 13, 2011

"Millions of servings of rare beef steak or completely raw steak tartare or carpaccio are served every day, so if that meat were inherently dangerous, we'd certainly know by now. Scientific investigation has confirmed the practice is reasonably safe—almost invariably, muscle interiors are sterile and pathogen-free. That's true for any meat, but only beef is singled out by the FDA. The cultural significance of eating raw and rare beef, as much as the Science, accounts for the FDA's/USDA/FSIS leniency in allowing the beef steak to be served at any internal temperature."

Dr. Baldwin recognizes in his book that you can cook your foods below 130F, but it will take a prolonged time to kill pathogens. But remember what I said earlier? If the food contains no pathogens, it was never necessary to kill pathogens to any D-Level (Log Reduction) because they were never there (see Mc Vol 1).

Unless you are cooking professionally and require a HACCP plan or are required to follow the FDA guidelines, there is no requirement to pasteurize. Now I don't want you to think I am against Pasteurization; on the contrary, I pasteurize 99.999999999% of everything I process.

Let's briefly discuss temps below 130f, for example, there are pasteurization tables that go as low as 125.6f published in the Modern Cuisine Books. Technically speaking, given enough time, you could pasteurize Chicken at 120f (See Mc Vol 1). But speaking practically, I can see absolutely no reason to process anything this low. So, the Caveat to what I just wrote is a cooking method that I call 2-Stage Processing (Warm-Aging). You can read about this method in the link above, but understand that you should pasteurize the protein if you choose to use this technique. As an option, a presear will kill potential surface pathogens, mitigating any latent issues. Also, if you are immune-compromised or are cooking for someone who happens to have this condition, you should take every precaution.

But I know what you are thinking: how can pasteurization tables go down to 125.6f when the dreaded food pathogen Clostridium perfringens can grow up to 126.1°F (52.3°C). I cover Clostridium perfringens a few paragraphs below. Also, look at the FDA Hazard Analysis and Risk-Based Preventive Controls for Human Food: Draft Guidance for Industry.

"So why were you taught that food pathogens don't multiply below 4.4◦C/40◦F and grow all the way up to 60◦C/140◦F? Because it takes days for food pathogens to grow to a dangerous level at 4.4◦C/40◦F (FDA, 2011), and it takes many hours for food to be made safe at just above 52.3◦C/126.1◦F "Baldwin Science Direct."

To give you some perspective, let's talk about Salmonella. Is Salmonella the most dangerous pathogen out there? No, but it's the most heat-resistant, so the FDA uses this as their standard. So if the thermal death cure of Salmonella reaches 6.5 D-reduction, other pathogens, i.e., like E.Coli, Listeria, and Staphylococcus, have been reduced to an even greater degree.

|

| MC Books Vol One Page 151 Microbiology for Cooks |

"While keeping the food sealed in its plastic pouches prevents recontamination after cooking, spores of C. botulinum, C. perfringens, and B. cereus can all survive the mild heat treatment of Pasteurization. Therefore, after rapid chilling, the food must either be frozen or held at

• below 2.5◦C/36.5◦F for up to 90 days,

• below 3.3◦C/38◦F for less than 31 days, • below 5◦C/41◦F for less than 10 days, or • below 7◦C/44.5◦F for less than 5 days."

A great read on Danger Zone and Food Safety by Peter Herztmann

The Complex Origins of Food Safety Rules--Yes, You Are Overcooking Your Food

Not to be a smart ass, but I have to ask this question again. If the food contains no pathogens, that means it was never necessary to kill pathogens to any D-Level (Log Reduction) because they were never there. Let's not forget when the Food Scientists created the Reduction tables, they used inoculated food (injected pathogens), which means the worst-case scenario. The FDA wants pathogen Reduction on poultry down to a 7D, a pathogen reduction of 10,000,000,000 to One. The Food Scientists told them that a 4.5D was more than adequate, but the Government wanted to keep us even safer. To go from 4.5D to 7D is not a massive jump in cooking temperature. If you're going to get into the weeds, I suggest reading Dr. Baldwin's footnotes and MCs (Modern Cuisine Books).

Here is Geeky, fascinating stuff for you. A Log reduction of 3d (99.9% pathogen reduction ) is adequate for healthy people, but an Immune-compromised person needs a 7D (D.E. Baldwin / International Journal of Gastronomy and Food Science 1 (2012) 15–3024). So what's the math? Let's take 137f, for example. If I process S.V. at 137f, how long would I have to hold to pasteurize to a Log Reduction Number of X? For a 3d (10.6 Minutes), 4.5d (15.92 Minutes), 6.5d (23 Minutes) and 7D (24.769 Minutes). Not a huge difference in times when cooking Sous-Vide. Most of us process in the 8-12D and don't realize we are achieving substantial Log Reductions. I remember I made this Chuck Roast, and I computed a 56D.

Now for some perspective. We understand that Salmonella starts to grow at 39f, and peak growth is at 107f, then decreases fast and begins to die at 120f. Based on the FDA, even if it spent 4-Hours at the peak temp, it still would be safe to eat. Are you still with me? Would it surprise you if I told you that the peak growth of 107f at 4-Hours produces the same amount of bacteria growth as 1.3 yrs at 39f? Wait, there is more. Not all temps within the danger zone are equally dangerous. Let's start with the most profound Temp and Time. The exact amount of Bacteria Growth achieved at 107f at 4 hours is the same amount as 39f at 1.3 years (previously stated), 50f 5-Days, 68f at 18-Hours, 86f at 7-Hours, and 118f at 5-weeks. The Salmonella Bacteria starts to die right above 118f (way faster at 120f) and stops growing below 39f but does not die. If a food is not already contaminated, leaving it out at room temp for 6-hours will most likely not pose any issue (don't do this).

But wait, how about Bacillus Cereus, which can survive up to 131? Yup. One of the least common foodborne illnesses and generally has the most negligible side effects. A study done in 1983 stated that the pathogen could survive up to 131f, but no one could replicate this, so it's invalidated. Generally, not an issue in foods with a high A.W. Google Bacillus when you get a chance. Cereus and Rice. See Baldwin Sous-Vide Review (Johnson et al. (, 1983) reported that Bacillus cereus could multiply at 55◦C/131◦F. Still, no one else has demonstrated growth at this Temperature. So C. perfringens is used instead.)

Update: Another paper that seems to contradict the above paragraph.

Ecological diversification in the Bacillus cereus Group

This brings us to Clostridium Perfringes. You have all

read that they can survive up to 126.1f. The fastest growth is 109.4-113f. However, growth can occur between 59f-122f (Labbe & Juneja, 2002). Growth outside this range requires strict anaerobic conditions. Growth at 126.1 was observed only under strict anaerobic conditions (Shoemaker & Pierson., 1976). Populations of C.Perfringens at temperatures below 50f have been reported to decline or remain stable, which infers the pathogens do not grow in the refrigerator. Also, Clostridium Perfringes and other spore-forming organisms only become an issue during cooling and not heating. I know what you are thinking; how about B. cereus, C. perfringens, and C. botulinum? Just like Salmonella is the indicator of safety, so is C. perfringens.

Why should C. perfringens be the indicator organism for the safety of cooling processes? Data from two studies on the outgrowth of B. cereus, C. perfringens, and C. botulinum, during cooling of inoculated (intentionally infected) cooked ground beef, demonstrated that C. perfringens multiplied by 4–5 log10 if cooling took 18 hours while the other two organisms did not grow during this Time. Of the three pathogenic spore-formers, C. Perfringens is most often associated with meat; improper holding temperatures and/or inadequate cooking contribute to nearly all outbreaks investigated by the CDC. Therefore, the outgrowth of C. perfringens is a logical choice as the standard to assess the safety of cooling processes. (Juneja VK, Snyder OP Jr, and Cygnarowicz Provost M. 1994. Juneja V.K. and Snyder OP Jr Marmer BS. 1997. Juneja VK, Whiting RC, Marks HM, and Snyder OP. 1999. Predictive model for growth of Clostridium perfringens at temperatures applicable to cooling of cooked meat. Food Microbiol 16(4):335–349. "

To keep things simple, let's focus on heating foods. Once the food gets above 125.6f (see Mc extended Pasteriztion table), all known pathogens stop growing (see comment above 126.1f). So on very long cooks, at low temps, as long as you pasteurize for Salmonella, you do not need to worry about the vegetative form of C. Perfringens.

Although C. Perfringens can produce toxins, it only does this while sporulating and is not really a concern when heating. The good news is the toxin is destroyed by heating (176f for a minimum of 10-Minutes but I always choose 180f to be on the safe side) {Response of Clostridium perfringens Spores and Vegetative Cells to Temperature Variation}.

The Vegetative form of C. Perfrigens could be a hazard but only occurs with the exploitation of Temperature. Pasteurizing for Salmonella is the mitigation for toxin proliferation. To limit the sporulating of C. Perfringens (since it creates its toxins while sporulating), cooling to below 40f should be done within 11 hrs (Snyder 1995). There is no concern when heating, but it can become a massive issue if temps are abused when cooling.

However, "Juneja et al. (1994c) reported that no appreciable growth (<1.0 log,)CFUIg) occurred if cooling took 15 h or less when cooked ground beef inoculated with heat-activated C. perfringens spores was cooled from 54.4 to 7.2°C at an exponential rate, that being more rapid cooling at the beginning followed by a slower cooling rate later. However, C. perfringens grew by 4 to 5 log10CFU/g if the cooling Time was greater than 18 h." Clostridium perfringens VIJAY K.JUNEJA, JOHNS.NOVAK, ANDRONALDJ. LABBE

A SHORT PODCAST ABOUT EVERYDAY RISKS FROM GERMS!!! It's more than just a podcast, and there are links to papers and safety-related food topics. It is hosted by Ben Chapman, an Associate Professor, and Extension Food Safety Specialist at North Carolina State University, and Don Schaffner, Distinguished Professor and Extension Specialist in Food Science and Professor at Rutgers University.

Comments

Post a Comment